Top 07 Reasons to use Laser Scanning for Construction Projects in 2026

By 2026, the global construction market will enter a significant paradigm shift, characterised by precision, data-driven processes, digital twins,...

10 min read

![]() Brighter Graphics

:

Jan 14, 2026 7:20:55 PM

Brighter Graphics

:

Jan 14, 2026 7:20:55 PM

By 2026, the global construction market will enter a significant paradigm shift, characterised by precision, data-driven processes, digital twins, and heightened demands for as-built construction verification. Amid tight schedules, rapid retrofit demands, and increasingly complex MEP systems, laser scanning (LiDAR) has evolved from an emerging technology into an operational necessity.

Recent industry data confirms this shift. More than three-quarters of AECO organisations (72%+) plan to increase their use of reality capture across all project phases by 2025. Laser scanning teams report up to a 70% reduction in time spent on manual verification, thereby boosting productivity and significantly reducing installation and renovation risk.

At the same time, owners and government agencies are enforcing ISO 19650 processes, requiring digital deliverables, and moving toward digital-twin-ready handover. With the growing volume of 2026-era building stock and the rise of sustainable MEP-intensive retrofit projects, outdated drawings and limited field measurements are no longer sufficient.

This article outlines the basics of LiDAR, point clouds, and Scan to BIM, helping you understand the top 7 reasons why laser scanning is an indispensable part of today's construction projects.

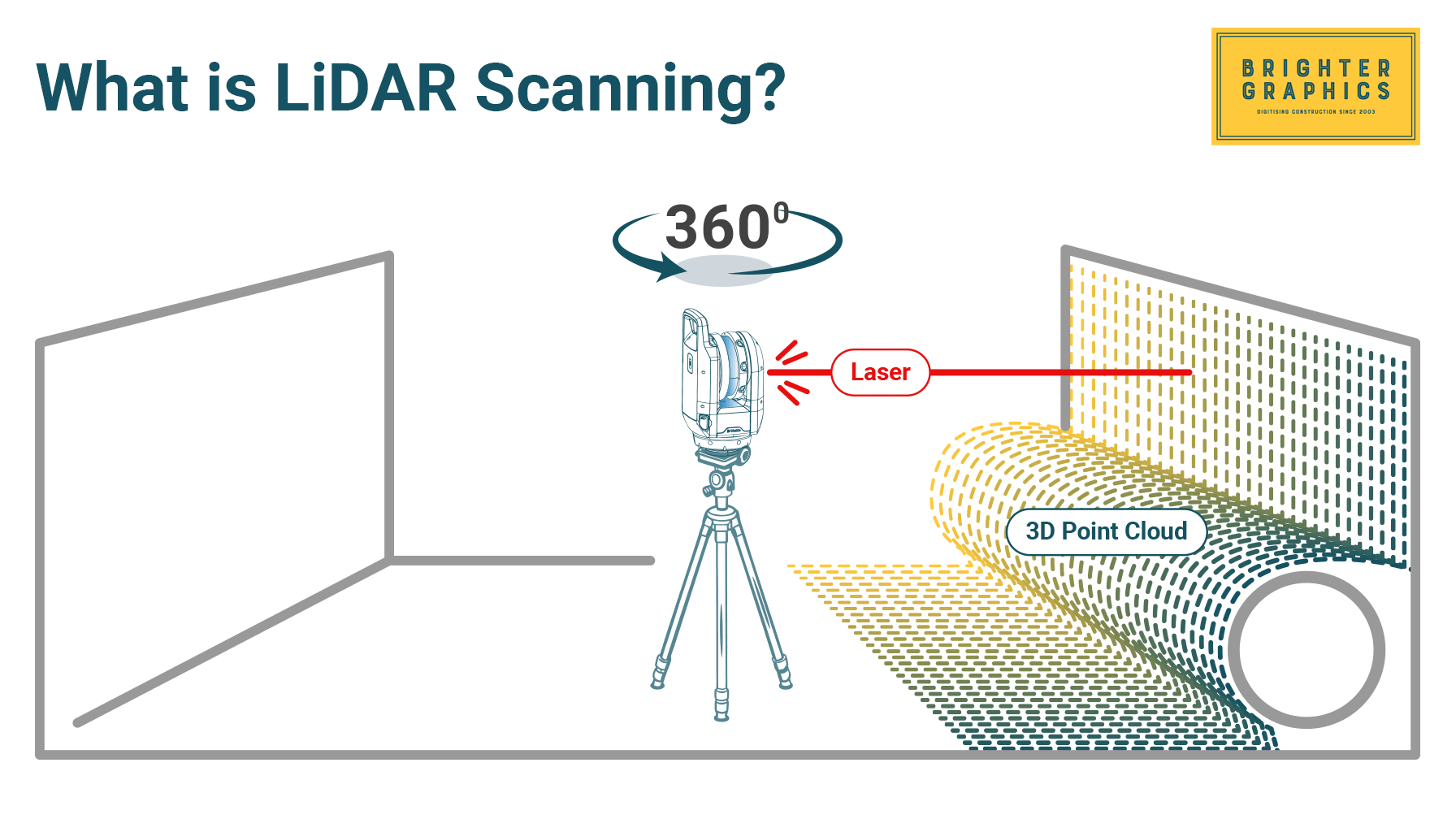

Laser scanning, or Light Detection and Ranging (LiDAR), is a non-contact measurement methodology/technology that projects thousands of laser pulses per second into the environment and records the precise range between the scanner and the target. Unlike traditional survey equipment, which records single points, LiDAR produces complete 3D data that illustrates the physical structure of a building, site, or asset.

Laser scanning is applied in construction to record:

Laser scanners can be installed on tripods, on carts, on drones, on robots, or in handheld devices, enabling teams to scan large, crowded, hazardous, or inaccessible environments.

The immediate result of a laser scan is a point cloud, a compact mass of many millions or even billions of XYZ data points. Every point is an accurate coordinate in space, and they all make an extremely accurate, photorealistic digital copy of the physical space.

The major features of a point cloud are:

The advantages of point clouds include the following in construction:

Modern construction data are now based on point clouds. They create the connection between the real world (the location) and the digital one (BIM, CDEs, digital twins).

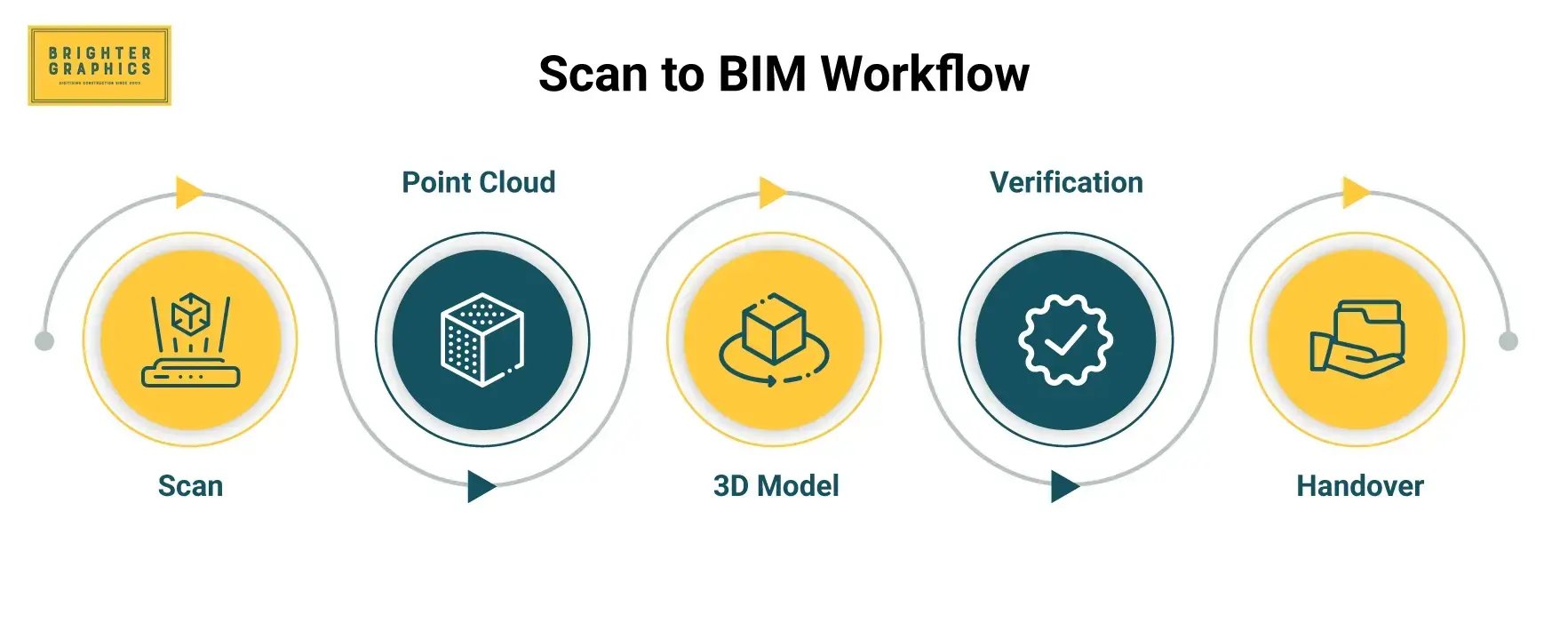

Scan-to-BIM is the process of transforming point cloud data into a structured, well-coordinated Building Information Model (BIM). It ensures that the digital representation of design models, coordination, fabrication, and lifecycle management accurately depicts proven reality, rather than previous drawings or approximate field representations.

The process usually has four key processes:

The building or site scan is conducted using TLS, mobile, drone, or robotic scanners. Several scans are taken to cover all areas.

All the scans are registered (merged) into a single point cloud. Any noise is eliminated, alignment is verified, and accuracy is checked.

The point cloud is interpreted, and an accurate BIM element is created by modellers, which includes:

This step adheres to the LOD guidelines (loot is usually 200 -500, based on the need).

Final models are compared to the point cloud by deviation maps or tolerance tests. The BIM model is subsequently provided in accordance with the project's EIR, AIR, or OIR.

-1.webp?width=1790&height=855&name=Scan%20vs.%20BIM%20(Verification)-1.webp)

Laser scanning is now considered a key element of construction delivery, driven by the global transition to digital engineering and the need for high-fidelity as-built data and automated processes. The following section discusses 07 reasons why construction leaders, contractors, and owners should embrace laser scanning to remain relevant and competitive in 2026 and beyond.

Laser scanning provides geometric accuracy that traditional surveying methods cannot match. Terrestrial Laser Scanners (TLS) routinely deliver millimetre-level accuracy (≈2-5 mm) while capturing millions of points per second. This stands in sharp contrast to sparse total-station shots and manual tape measurements, which capture limited data and are susceptible to human error.

The resulting point cloud has redefined how as-built conditions are documented across the AECO industry. For renovation, retrofit, and brownfield projects, teams can no longer rely on legacy information sources, including:

This challenge is particularly acute in existing buildings, industrial and plant facilities, and complex MEP environments, where deviations from the original design are common, and documentation is often unreliable or nonexistent.

Scan-to-BIM converts high-density point clouds into BIM models that reflect actual existing conditions rather than assumptions. The resulting model becomes the single source of geometric truth, supporting design, coordination, construction, and facility management throughout the asset lifecycle.

This approach enables:

As a result, asset owners are increasingly specifying Scan-to-BIM deliverables in contractual requirements, particularly for hospitals, data centres, airports, and industrial facilities, where precision and operational continuity are critical.

From an information management perspective, Scan-to-BIM aligns directly with ISO 19650. The standard requires BIM models to contain accurate, verifiable, and traceable information that satisfies:

Laser scanning is the only practical method capable of supplying as-built geometry that meets these requirements with sufficient reliability.

Looking toward 2026 and beyond, Scan-to-BIM research and development continue to accelerate automation through AI-based semantic segmentation, automated element recognition, semi-automated extraction of walls, pipes, and ducts, and improved point cloud registration and cleaning. These advances are significantly reducing manual modelling time while improving consistency and scalability.

Together, these trends explain why point clouds are rapidly becoming the default input for any serious BIM, retrofit, or asset modernisation project, forming the foundation for reliable, ISO-compliant digital asset workflows.

For complex assets and industrial facilities, subjective progress monitoring is no longer acceptable. Owners increasingly demand digital traceability, objective verification, and defensible QA/QC, driving the shift toward data-driven progress monitoring as standard practice by 2026. Traditional monitoring methods are too slow, inconsistent, and difficult to validate against modern project requirements.

Research studies conducted from 2024 to 2026 consistently show that integrating BIM with laser scanning improves the accuracy of progress tracking and significantly reduces manual inspection effort. Laser scanning enables objective, measurable, and repeatable progress tracking, replacing opinion-based assessments with spatial evidence captured directly on site.

Periodic LiDAR scans (daily, weekly, or milestone-based) are registered and aligned with the design or 4D BIM model. Automated point cloud-to-BIM comparisons then determine what has been built, what is missing, and where work falls outside allowable tolerances.

Additionally, the AI-driven semantic segmentation further enhances this workflow by automatically classifying elements such as walls, slabs, beams, ducts, and piping. This allows construction progress to be assessed at an element and trade level rather than through manual inspection.

As a result, teams can automatically generate:

Laser scanning has become a key tool for structural health monitoring (SHM) due to its high precision, non-contact operation, and ability to capture full-surface geometric data. By performing multi-epoch scans over months or years, engineers can detect even minute changes that traditional sensors or infrequent inspections might miss, including:

This high-density point cloud data allows detection of millimetre-level movement, providing comprehensive insight into structural behaviour.

Laser scanning complements existing SHM sensors like strain gauges, LVDTs, and accelerometers by providing full-field, high-density geometry, giving context to single-point measurements that conventional instruments cannot capture.

With governments and asset owners increasingly requiring digital inspection and lifecycle documentation, LiDAR provides a reliable, long-term geometric record necessary for maintaining safety, managing risk, and enabling predictive maintenance, making it an essential part of modern SHM practice.

By 2026, digital twins will evolve from experimental tools into standard platforms for operational, maintenance, asset management, and long-term planning. A digital twin integrates geometry (BIM), time, sensor, and IoT data, analytics, and simulation models into a single virtual entity. However, the foundation of any reliable digital twin is accurate geometry, which can only be ensured through laser scanning.

Without precise spatial representation, connected systems such as energy modelling, structural simulation, asset tracking, or predictive maintenance cannot produce correct outputs. Laser scanning provides:

A digital twin built on inaccurate geometry is essentially unusable; laser-scanned data ensures trustworthiness from the outset.

Large-scale digital twin programs, such as those in the UAE, explicitly require LiDAR-based as-built geometry as the foundation. Digital-twin-ready deliverables are increasingly becoming a standard requirement in contracts, reflecting a global trend toward accurate, geometry-driven asset management.

Safety is a core priority in modern construction and asset management. Laser scanning reduces the need for people to physically enter dangerous environments, making it a practical safety-by-design and by-data tool by 2026, strongly aligned with HSSE and broader ESG objectives.

Laser scanning allows teams to collect dense, accurate geometry from safe stand-off distances. In many cases, this removes the need to work at height, erect scaffolding or ladders, enter confined spaces, close traffic lanes, or access live rail corridors.

Fewer people in harm’s way means lower risk for surveyors, engineers, and construction crews. This approach is particularly effective in environments such as:

Conventional surveys often take days, require multiple crews, safety spotters, and sometimes heavy access equipment. A single LiDAR operator can frequently capture the same area in hours, resulting in:

Contractors commonly report 40-60% reductions in time spent in high-risk environments, directly supporting improved safety performance and lower insurance exposure.

By 2026, these benefits will be amplified through integration with other platforms. Scanners are increasingly deployed on tripods, mobile carts, ground robots, and UAVs for façades, bridges, plants, and tunnels. While some of this is still emerging, the trend is clear: faster coverage, broader access, and even less human exposure to danger.

Rework is one of the largest cost burdens in construction, accounting for approximately 5-12% of the total project value. Most rework results from incorrect measurements or unknown existing conditions. Laser scanning removes this uncertainty by capturing accurate representations of real-world conditions before construction or retrofit work begins.

For MEP and retrofit projects, laser scanning significantly improves coordination and constructability, particularly in constrained environments. Key advantages include:

Industry case studies consistently demonstrate the impact of laser scanning on project performance. Contractors frequently report:

Laser scanning has become a strategic requirement as BIM standards, data governance, and client expectations continue to evolve beyond 2026. Asset owners increasingly require verified as-built models, digital twins, and cloud-based Common Data Environments (CDEs) delivered in compliance with ISO 19650.

In addition, owners now expect data that is accurate and reliable, fully traceable, and lifecycle-ready for long-term asset management. These requirements cannot be consistently met using traditional surveying methods, making high-fidelity reality capture the only scalable solution.

Advances in AI between 2026 and 2028 are expected to significantly improve:

Organisations that adopt laser scanning now will be well positioned to take advantage of these capabilities, while late adopters risk costly, rushed, and disruptive transitions.

Laser scanning technology continues to mature, becoming more automated, accurate, and affordable. The availability of global reality-capture services also enables adoption without the need for dedicated in-house scanning teams.

Failure to adopt laser scanning increases project risk, weakens documentation quality, reduces competitiveness during bidding, and limits the ability to meet client and ISO 19650 delivery expectations. Owners demand certainty and reliability, and laser scanning delivers both.

The construction industry is undergoing a radical transformation. Any successful project is based on data, not drawings, assumptions, and manual measurements. Laser scanning (LiDAR) provides the most precise information available, enabling the integration of point clouds, BIM, coordination, QA/QC, prefabrication, and digital twins into a single ecosystem.

Laser scanning can help teams to work smarter with millimetre-precise as-builts, lifecycle structural monitoring, automated progress tracking, risk-free prefabrication, and more. It converts uncertainties into quantifiable facts and simplifies complexities.

Laser scanning is no longer an option, as 2026 demands greater strictness, more demanding owners, and a more digital workflow.

The future of construction is digital, and laser scanning lies at its centre.

Brighter Graphics’ Digital Engineering

Our Digital Engineering technology brings together laser scanning, Scan to BIM, BIM coordination, construction verification, and virtual asset management.

Our objective is to assist you in capturing, structuring, and operationalising your data, whether you are upgrading facilities, undertaking new construction, or preparing for lifecycle operations that afford digital representations of the physical environment.

Interested in getting started with your site capture?

No need to purchase expensive equipment and hire or train people in-house. Our Digital Engineering team brings you all the expertise that you need with high-end scanning equipment. Explore our Digital Engineering services today or speak to us to discuss how we can transform the way you build our world.

By 2026, the global construction market will enter a significant paradigm shift, characterised by precision, data-driven processes, digital twins,...

The new Bluebeam Revu update, version 21.8, is now available. The latest version focuses on simplifying workflows, improving collaboration, and...

When it comes to construction, “close enough” just doesn’t cut it anymore. Owners expect consistent schedules, contractors want zero rework, and VDC...